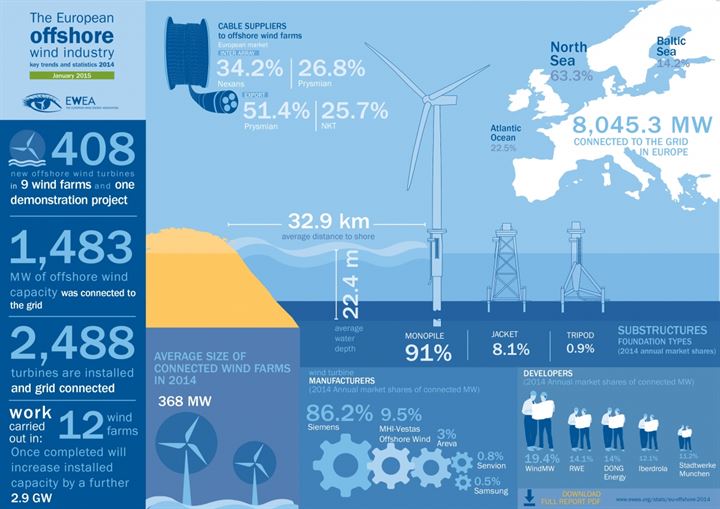

According to the report of EWEA (The European Wind Energy Association) on the development of the European wind offshore industry in the first half of 2015, the new offshore capacity installations were up 200% compared to the same period the previous year. Overall, 584 commercial offshore wind turbines were fully grid connected, with a total capacity of 2,342.9 MW. 15 commercial wind farms were under construction, which ones completed would have a total capacity of over 4,268.5 MW.

The European Offshore Wind Energy Sector in 2104, source: EWEA

The first prototypes of a fixed offshore wind turbine – the Statoil’s Hywind, installed in 2009 in the south-west coast of Norway and a floating offshore wind turbine – the Principle Power’s WindFloat in 2012 in Portugal, have marked the emergence of a new industrial sector. Since that moment, many industrial key players are producing state-of-the-art technologies to capture wind energy in deep-water environments. Most of the installations are adapted to deep waters close to large power consumption regions throughout the world, which offers appealing market opportunities. The extensive investment and stable income returns of the offshore wind sector continue to attract institutional investors.

Also, as part of the energy diversification policies of European states, offshore wind energy represents THE consistent source of marine renewable energy with continuously expanding capacities.

Advantages of Offshore Wind Energy

The wind is an unlimited, free, renewable resource.

Undoubtedly the biggest advantage of offshore wind energy projects over onshore ones is the strong and frequent wind power. Since wind is a natural resource, harvesting its kinetic energy, doesn’t have any impact on wind patterns.

Harnessing wind power is an environmentally friendly way to generate electricity.

If properly installed with a respect to nearby marine ecosystems, offshore wind farms have smaller to none impact on the landscape. Also, compared to conventional power plants, offshore wind turbines emit no air pollutants or greenhouse gases.

Offshore Wind Turbines Can Be Placed Wherever Necessary.

Once sites with according wind patterns have been identified and tested, turbines can be installed in the desired areas. In general, they can be placed anywhere wind currents are present.

The Transport of Big Wind Turbine Components is Easier.

Ships can handle far easier the transportation of tower sections, nacelles and blades than trucks and trains the components of onshore wind turbines.

The Maintenance Cost of Installed Offshore Wind Farms is Next to Nothing.

Once offshore wind turbines have been installed and connected to the grid, they require minimal cost to be maintained.

Floating or Fixed Offshore Wind Turbines?

Fixed offshore wind turbines are constrained by water depth. Conventional installation techniques as monopiles, jackets and other fixed structures are only suitable for water up to 50 meters deep. This might be a good option for the coasts of northern Europe, where coastal waters are relatively shallow, but not for places, where continental shelf drops suddenly and make installation of fixed structures much more laborious.

While avoiding depth limitations, floating wind power offers 600 GW offshore European coastal capacity. Recently French government has recognized this potential and launched a tender for 4 floating offshore wind farms. This is considered the first European tender of such a big size. The identfied areas include Leucate, Brescou and Fos-sur-Mer on the Riviera where sea floor slopes steeply. A fourth area is around the island of Ile de Groix, off southern Brittany.

FMGC Innovative Solutions Can Solve some of the Challenges of the Floating Offshore Wind Energy Sector

Floating offshore wind farms can harness the wind energy in deep waters, without requiring any expensive and difficult-to-install subsea infrastructure. To restrict their movements, high-quality mooring systems are required. The interaction with wind-and-wave induced forces raise many technical challenges and makes strong and reliable anchoring of critical importance. A high-quality offshore mooring system should hold the offshore floating turbines firmly in place, eases the installation and maintenance of the device and all this in a highly reliable and cost-effective way. Floating offshore wind farms need to be powerfully built in order to withstand rough weather conditions. This induces high constructions costs and put the spotlight on mooring lines, making them one of the most important components.

Relying on its longstanding expertise in the manufacture of heavy sets of counterweights for the off-highway industry, FMGC supplies the MRE sector with diverse innovative ballast solution, technically adapted to the needs of the floating offshore wind industry. Major manufacturers of mooring systems have already trusted the following FMGC products, mainly because of their high-quality/ cost-efficiency ratio:

Clump Weights

FMGC clump weights are available as “distributed” and “mutualized” configuration.

Mutualized Clump Weight Distributed Clump Weight

Both are made of cast iron and are designed to offset the vertical forces against the anchor and restrict the movements of the floating structure. Thanks to FMGC clump weights, the length and the dimensions of the entire anchoring system can be significantly reduced. All clump weights can be manufactured with a customized design, based on the target weight, the chain line diameter and the available installation means.

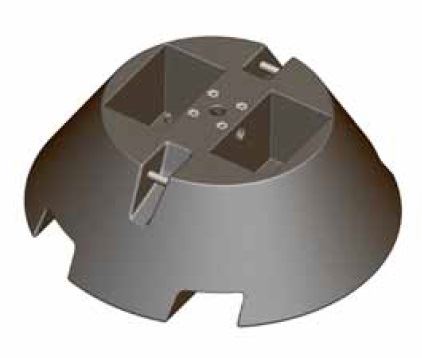

Gravity Anchors

Gravity anchors offer an excellent alternative to the conventional ones in order to pool together various anchors to a larger scale. All FMGC gravity anchors are made of cast iron, which increases their density and minimizes the mass required to stabilize the anchor. FMGC is leading European supplier of cast iron counterweights for diverse industries and is specialized in the manufacture of optimized assemblies, weighing up to several hundred tonnes.

As an emerging industry the floating offshore wind sector needs a solid supply base to secure its future and makes it truly competitive and sustainable in the long term. This is a dynamic industry with a lot of potential, but still facing many technical challlenges, mainly because all employed technologies are new and need to be tested. FMGC engineeres monitor closely the sector and are aware of all challenges and obstacles. All our solutions are tailored to the very specific needs of the offshore floating wind industry and aim at reducing cost and easing installation and maintenance.